In the landscape of modern process engineering and thermal management, plate heat exchangers (PHEs) have evolved into a paramount technology, addressing the industry’s escalating demands for energy efficiency, operational sustainability, and process optimization. As sectors ranging from manufacturing to HVAC prioritize resource conservation and performance enhancement, a comprehensive understanding of the design principles, technical advantages, and industrial applicability of plate heat exchangers becomes indispensable. This article elaborates on the core characteristics of PHEs, their superior performance relative to conventional heat transfer equipment, and the rationale behind their widespread adoption across diverse industrial domains.

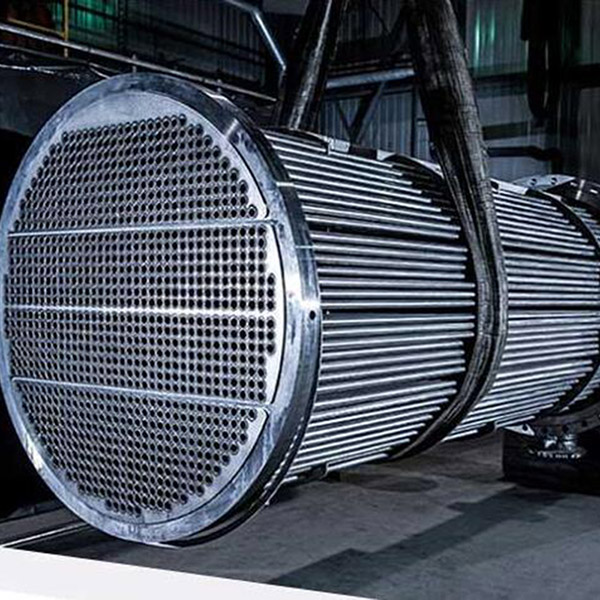

A plate heat exchanger is a specialized thermal transfer device that utilizes corrugated metal plates as heat exchange surfaces to facilitate efficient thermal energy transfer between two or more incompatible process fluids. This design deviates fundamentally from conventional shell-and-tube heat exchangers (STHEs), which rely on tubular bundles for heat transfer. The innovative plate-based configuration—characterized by thin, spaced plates with engineered surface geometries—delivers exceptional thermal efficiency and structural compactness, redefining performance benchmarks for heat exchange systems.

The mechanical design of PHEs revolves around a stack of thin, corrugated metal plates, typically constructed from materials such as stainless steel, titanium, Hastelloy, or aluminum, depending on fluid compatibility and operating conditions. These plates are separated by gaskets (in gasketed designs) or joined via brazing/welding (in brazed/welded variants), forming alternating flow channels for the hot and cold fluids. The corrugated surface geometry serves dual purposes: it maximizes the effective heat transfer area per unit volume and induces turbulent flow within the channels, minimizing thermal resistance at the fluid-solid interface. Fluids are distributed uniformly across the plate surfaces, ensuring intimate contact and efficient heat transfer through conduction and convection.

Plate

heat exchangers are classified into four primary configurations, each tailored to specific industrial requirements:

- Gasketed Plate Heat Exchangers (GPHEs): Featuring removable plates sealed with elastomeric gaskets, ideal for low-to-medium pressure (up to 20 bar) and temperature (up to 150°C) applications where flexibility and easy maintenance are critical.

- Brazed Plate Heat Exchangers (BPHEs): Manufactured via vacuum brazing, offering enhanced structural integrity for high-pressure (up to 100 bar) and high-temperature (up to 300°C) operations, commonly used in refrigeration and industrial process heating.

- Welded Plate Heat Exchangers: Designed with fully welded plate packs, suitable for corrosive, toxic, or high-pressure fluids (exceeding 100 bar) where gasket failure is a concern, such as in chemical processing.

- Semi-Welded Plate Heat Exchangers: Combining welded channels for aggressive fluids with gasketed sections for non-corrosive streams, balancing durability and operational flexibility.

The adoption of plate heat exchangers is driven by a suite of technical and operational advantages that outperform traditional heat transfer equipment:

1. Exceptional Thermal Efficiency

PHEs deliver superior heat transfer coefficients (U-values), typically 2–5 times higher than shell-and-tube exchangers, due to turbulent flow induction and extended surface area. The corrugated plate design disrupts laminar flow, reducing boundary layer thickness and promoting efficient heat transfer—enabling achieves target thermal duty with a smaller footprint.

2. Compact Footprint and Space Efficiency

The modular, stackable design of PHEs results in a 50–70% smaller installation footprint compared to shell-and-tube exchangers of equivalent thermal capacity. This space-saving attribute is critical for retrofitting existing facilities, offshore platforms, or urban industrial sites where spatial constraints are prohibitive.

3. Energy and Cost Savings

High thermal efficiency translates directly to reduced energy consumption, as PHEs require lower pumping power and heating/cooling inputs to achieve the same heat transfer performance. Over the lifecycle, this translates to substantial operational cost savings, complemented by lower capital expenditure due to their compact design and modular scalability.

4. Operational Flexibility and Scalability

PHEs offer unparalleled flexibility: capacity can be adjusted by adding or removing plates without modifying the core system, accommodating fluctuating process demands. Their modular construction also facilitates easy disassembly for inspection, cleaning, and fouling mitigation—minimizing downtime and maintenance costs compared to the complex tube cleaning required for shell-and-tube exchangers.

5. Hygienic and Corrosion-Resistant Design

For industries such as food and beverage, pharmaceuticals, and biotechnology, PHEs meet stringent hygienic standards (e.g., 3-A, EHEDG) with smooth, crevice-free plate surfaces that prevent bacterial growth. Additionally, material customization (e.g., titanium for seawater, Hastelloy for acidic fluids) ensures corrosion resistance, extending service life in aggressive environments.

Plate heat exchangers are deployed across a broad spectrum of industries, leveraging their efficiency, compactness, and flexibility to address diverse thermal management needs:

- HVAC and Building Services: Used in heat recovery ventilation (HRV) systems, chilled water loops, district heating/cooling networks, and geothermal heat pumps—optimizing energy use in commercial and residential buildings.

- Refrigeration and Air Conditioning: Employed as condensers, evaporators, and subcoolers in industrial refrigeration systems, cold storage facilities, and HVAC chillers—enhancing system efficiency and reducing refrigerant charge.

- Chemical and Petrochemical Processing: Critical for process fluid preheating, reaction temperature control, solvent recovery, and waste heat recovery—ensuring precise thermal management in corrosive and high-pressure environments.

- Food and Beverage Industry: Utilized in pasteurization (dairy, juices), sterilization, beer wort cooling, and syrup concentration—maintaining product integrity and compliance with hygienic regulations.

- Pharmaceuticals and Biotechnology: Applied in API purification, fermentation temperature control, and clean-in-place (CIP) systems—supporting sterile processing and regulatory compliance (e.g., FDA, EMA).

- Marine and Offshore: Used for engine cooling, seawater desalination, and HVAC systems on ships and offshore platforms—benefiting from their compact design and corrosion-resistant materials.

Comparative Advantages Over Shell-and-Tube Exchangers

- Higher Thermal Efficiency: Turbulent flow and extended surface area result in U-values significantly exceeding those of shell-and-tube exchangers, reducing energy consumption and equipment size.

- Easier Maintenance: Removable plates allow for targeted cleaning, inspection, and replacement—eliminating the need for tube brushing or chemical descaling, which is labor-intensive and time-consuming.

- Lower Environmental Impact: Optimized energy use reduces carbon emissions, aligning with industrial sustainability initiatives (e.g., ISO 50001 energy management systems) and circular economy goals.

- Reduced Fluid Hold-Up: Minimal volume of fluid within the exchanger reduces product loss and environmental risk in processing applications involving hazardous or high-value fluids.

Key Considerations for Selection

To ensure optimal performance and longevity, several critical factors must be evaluated when selecting a plate heat exchanger:

- Material Compatibility: Plates and gaskets must be compatible with process fluids to mitigate corrosion, erosion, and chemical degradation. Common materials include stainless steel (for aqueous solutions), titanium (for seawater and chlorides), and Hastelloy (for aggressive chemicals).

- Operating Parameters: Pressure and temperature ratings must align with process conditions—gasketed PHEs are suitable for low-to-medium ranges (up to 20 bar, 150°C), while brazed/welded designs handle high-pressure (exceeding 100 bar) and high-temperature (up to 300°C) applications.

- Flow Configuration: Counterflow, parallel flow, or crossflow arrangements impact thermal efficiency—counterflow is preferred for maximum log mean temperature difference (LMTD), optimizing heat transfer performance.

- Fouling Potential: Fluid properties (viscosity, particle content, chemical composition) influence fouling rates; plates with specialized surface treatments (e.g., anti-fouling coatings) or wider flow channels may be required for fouling-prone fluids.

Future Trends and Innovations

The evolution of plate heat exchangers is shaped by ongoing advancements in materials science, design engineering, and digitalization:

- Advanced Materials: Development of nanocomposite coatings, refractory alloys, and polymer-ceramic hybrids is expanding PHE applicability to extreme environments (e.g., high-temperature industrial processes, corrosive chemical streams).

- Smart Monitoring and Control: Integration of IoT-enabled sensors, predictive maintenance algorithms, and digital twins allows real-time monitoring of temperature, pressure, fouling rates, and gasket integrity—enabling proactive performance optimization and minimizing unplanned downtime.

- Sustainable Design: Focus on recyclable materials, energy-efficient geometries, and waste heat recovery capabilities is aligning PHEs with global sustainability agendas, such as the Paris Agreement and net-zero carbon targets.

- Modular and Compact Systems: Miniaturized PHE designs for microprocesses (e.g., lab-scale chemical synthesis, portable HVAC) and modular skid-mounted units for rapid deployment are expanding their application scope.

Plate heat exchangers represent a pioneering advancement in thermal engineering, offering a compelling combination of superior efficiency, compact design, operational flexibility, and cost-effectiveness. Their ability to address diverse industrial needs—from energy-intensive manufacturing to hygienic food processing—underscores their role as a cornerstone of modern thermal management systems. By outperforming conventional heat exchangers in key performance metrics and aligning with sustainability objectives, PHEs have become the preferred choice for industries seeking to optimize resource use, reduce operational costs, and enhance process reliability.

As global industries continue to prioritize energy efficiency, environmental stewardship, and process innovation, the demand for advanced plate heat exchangers is poised to grow. With ongoing technological advancements in materials, design, and digitalization, PHEs will remain at the forefront of thermal management solutions, driving progress toward more sustainable, efficient, and resilient industrial processes.