Analysis of the Structure Principle and Application of Tubular Heat Exchangers

Release time:2025-10-18

Visits:329

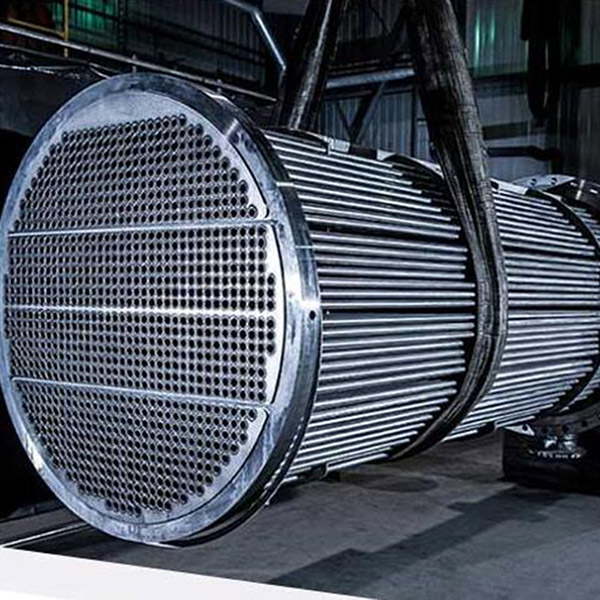

Tubular heat exchangers (also known as shell-and-tube heat exchangers) are widely used heat exchange equipment in the industrial field. Their core function is to transfer heat between two fluids through the tube wall, which is suitable for heating, cooling, or condensation processes in industries such as chemical, petroleum, power, and food.

Core Structure and Function

1. Shell: As the main framework, the shell encloses the tube bundle and accommodates the shell-side fluid. Its design needs to withstand high temperature and pressure, and the common materials are carbon steel or stainless steel.

2. Tube Bundle and Tube Sheet: The tube bundle is composed of multiple parallel heat exchange tubes, which are fixed at both ends by drilled tube sheets to form independent tube-side channels. The materials of the tube bundle can be selected from copper, titanium, etc., according to the corrosiveness of the fluid.

3. Head and Inlets/Outlets: The heads located at both ends of the shell are responsible for sealing the fluid and are equipped with inlets and outlets for the tube-side fluid to ensure the directional flow of the medium.

4. Baffles: The baffles installed inside the shell can change the flow path of the shell-side fluid, prolong the contact time, and enhance the turbulent flow effect, thereby improving the heat transfer efficiency.

Working Principle

Tubular heat

exchangers achieve heat exchange between hot and cold fluids through partition wall heat transfer:

- Separation of Tube-side and Shell-side: The high-temperature fluid enters the inside of the tube bundle (tube-side), and the low-temperature fluid flows around the tube bundle (shell-side).

- Heat Transfer: Heat is conducted from the high-temperature side to the low-temperature side through the tube wall. The cold fluid absorbs heat and rises in temperature, while the hot fluid releases heat and drops in temperature.

- Flow Optimization: The baffles force the shell-side fluid to scour the tube bundle transversely multiple times, enhancing the turbulent flow, reducing fouling, and improving the heat exchange efficiency.

Advantages and Limitations

Advantages:

1. The structure is stable and can adapt to high-pressure, high-temperature, and corrosive medium environments.

2. The modular design of the tube bundle facilitates cleaning and maintenance, extending the service life.

3. By adjusting the number of tube bundles and the layout of the baffles, it can flexibly meet the requirements of different working conditions.

Limitations:

1. It has a large volume and requires a relatively large installation space.

2. High-viscosity or easily fouling fluids will reduce the heat transfer efficiency, and regular chemical cleaning or mechanical descaling is required.

3. The manufacturing cost is higher than that of compact heat exchangers such as plate heat exchangers, making it suitable for medium and large-scale industrial scenarios.

Industry Applications

- Petrochemical Industry: Used for preheating crude oil, controlling the temperature of reactors, and cooling finished products.

- Power and Energy Industry: Heating feedwater in boiler systems or condensing steam in steam turbines.

- Food Processing Industry: Performing pasteurization or rapid cooling on fruit juices and dairy products.

- Pharmaceutical Field: Ensuring precise temperature control of fermentation tanks and distillation equipment.

Development Trends

With the increasing demand for industrial energy conservation, the technological innovation of tubular heat exchangers focuses on:

1. Enhanced Heat Transfer: Developing new tube bundle structures such as corrugated tubes and finned tubes to expand the effective heat transfer area.

2. Corrosion-resistant Materials: Using composite materials or surface coating technologies to extend the service life of equipment under extreme working conditions.

3. Intelligent Monitoring: Integrating sensors to monitor the flow rate, temperature, and pressure in real time, optimizing energy efficiency, and providing early warnings for faults.

Data shows that the global heat exchanger market scale is expected to exceed 150 billion yuan in 2025. Among them, tubular heat exchangers will still occupy the mainstream position in heavy industries such as petroleum and chemical industries due to their reliability and adaptability. When selecting models, enterprises need to comprehensively consider fluid characteristics, working condition parameters, and maintenance costs to achieve efficient and stable thermal energy management.