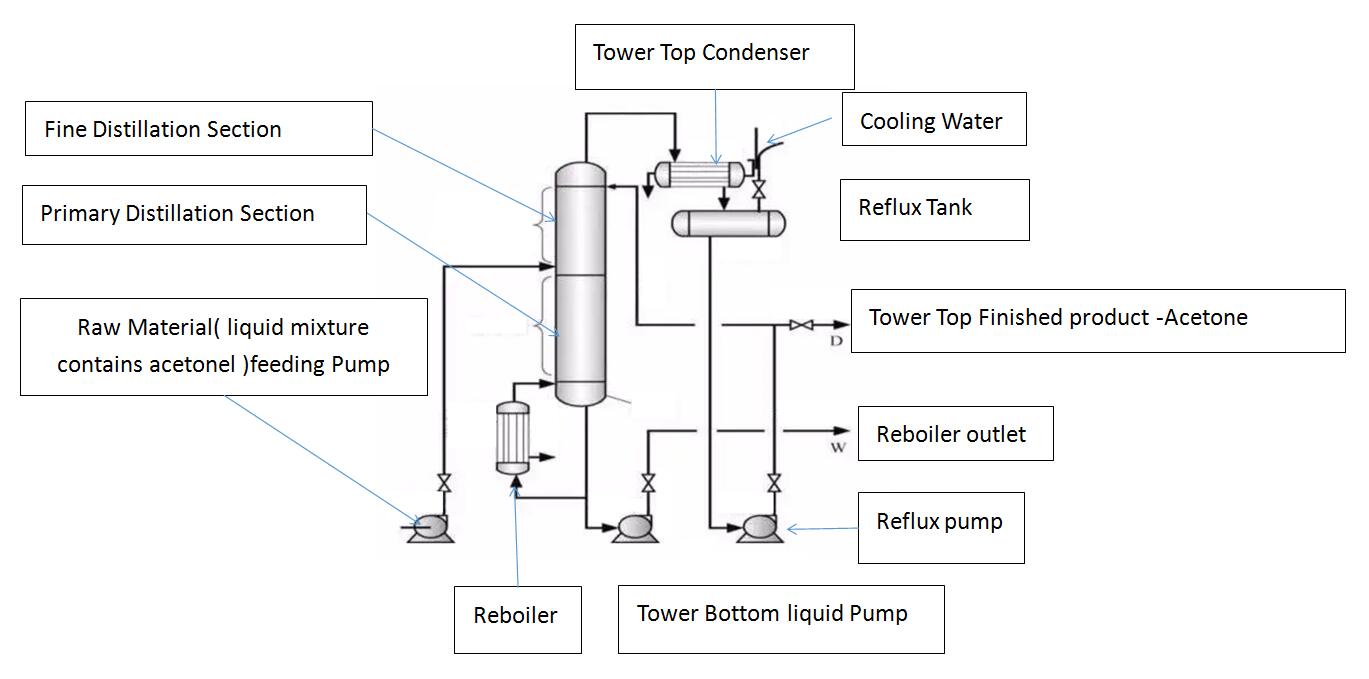

Overview of acetone distillation tower

High separation efficiency Acetone Distillation Tower is a commonly Distillation tower equipment, and Wuxi Hongdinghua Chemical Equipment Co., Ltd. (HDH) has years of experience in designing and manufacturing Acetone Distillation Towers.

Acetone is an important organic synthetic raw material used in the production of epoxy resins, polycarbonates, organic glass, pharmaceuticals, pesticides, etc. It is also a good solvent for coatings, adhesives etc. It is also used as a diluent, cleaning agent, and extractant. It is also an important raw material for manufacturing acetic anhydride, diacetone alcohol, chloroform, iodoform, epoxy resin, polyisoprene rubber, etc. Used as a solvent in industries such as smokeless gunpowder, celluloid, acetate fiber, and spray paint, as well as as as an extraction agent in industries such as grease.

So it is very important to concentrate and recycle acetone, Wuxi Hongdinghua Chemical Equipment Co., Ltd. has rich experience in recovering acetone from acetone solutions under various conditions. The Acetone Distillation Tower designed and manufactured by HDH has a wide range of applications in various industries.

Wuxi Hongdinghua Chemical Equipment has regular demand of designing and manufacturing Acetone Distillation Towers from customers for many years. Acetone distillation towers are widely accepted by customers in industries such as chemical, pharmaceutical, and environmental protection. Acetone distillation tower is widely used as an equipment of gas-liquid mass transfer equipment in production. According to the form of gas-liquid contact components inside the tower, it can be divided into Packing type Acetone Distillation Tower and Plate type Acetone Distillation Tower. The plate type acetone distillation tower belongs to stepwise contact countercurrent operation, while the Packing type acetone distillation tower belongs to differential contact operation.

The main requirements for acetone distillation tower equipment in industry

The reasonable selection of acetone distillation tower type is the primary step in the design of Acetone Distillation Tower. When selecting, the following should be considered

1. Specifications of Materials

2. Acetone Distillation Tower’s operating conditions

3. Performance of Acetone Distillation Tower

4. Factors related to the manufacturing, installation, operation, and maintenance of Acetone Distillation Tower.

The basic performance indicators of acetone distillation tower mainly include

1. Yield and flux: Yield refers to the amount of material processed per unit time, while flux refers to the amount of material processed per unit time on a unit tower cross-section.

2. Separation efficiency: For a plate tower, it refers to the degree of separation that each layer of tray can achieve. The packing tower is the separation capacity per unit height of the packing layer.

3. Adaptability and operational flexibility: The ability to adapt to various material properties and maintain stable operation and high separation efficiency during load fluctuations.

4. Fluid resistance: The pressure drop of the gas phase through each layer of tray or unit height packing layer.

Wuxi Hongdinghua fully considers the following factors for customers in designing and manufacturing acetone distillation towers

Cost of Acetone Distillation Tower

2. The difficulty of installation and maintenance

3. Factors such as long-term operational reliability

Provide parameters and technical data

HDH will ask your to provide following technical data, parameters and material specifications when HDH is doing designing and manufacturing for you as following:

(1) Raw Material Feeding amount per unit time: _____

(2) Detailed composition of raw materials: _____

(3) Tower top output amount _____kg/h, with a concentration requirement of _____%;

(4) Tower bottom output amount _____kg/h, with a concentration requirement of _____%;

(5) Whether the material has thermal sensitivity: □; Please specify: _____

(6) Corrosion: _____ ;

(7) Operating flexibility: _____upper limit; _____Lower limit;

(8) Operating time: _____hours/day;

(9) Cooling water temperature (inlet/outlet): _____℃ in summer, _____℃ in winter;

(10) Chilled water temperature (inlet/outlet): _____ ℃;

(11) Steam pressure (gauge pressure): _____MPa

(12) Heat transfer oil temperature: _____℃;

(13) Installation environment: indoor □;outdoor □

(14) Meteorological environmental conditions

(15) Selection conditions for electrical equipment (Electric Power Supply Condition) _____

Details of acetone distillation tower

Acetone distillation tower is a widely used mass transfer equipment in production processes such as chemical, petrochemical, biochemical, pharmaceutical, etc. According to the structural form of gas-liquid contact components in the Acetone Dstillation Tower, Acetone Distillation Tower can be divided into two categories: plate type acetone distillation tower and packing acetone distillation tower.

A certain number of trays are installed in the plate type acetone distillation tower, where gas passes through the liquid layer in the form of bubbles or jets for mass and heat transfer. The tray is the main component of the plate type acetone distillation tower, which is divided into two categories: cross flow tray and counter flow tray. Industrial applications mainly use cross flow tray, and commonly used cross flow tray mainly includes the following types:

(1) Bubble cover tray

(2) Sieve tray

Advantages of sieve tray tower: simple structure and low cost; The airflow pressure drop is small, and the liquid level drop on the board is small. The board efficiency is high.

(3) Float valve tray

The advantages of float valve trays are simple structure, convenient manufacturing, low cost, and high opening rate of trays. However, their disadvantages are that when dealing with coking and high viscosity systems, the valve plates are prone to bonding with the trays, resulting in jamming and other phenomena during operation, which reduces the operating flexibility of the trays.

Operating conditions for acetone distillation tower

Operating pressure

The operation pressure of acetone distillation tower can be carried out under atmospheric pressure, negative pressure, and pressurized. The pressure has a significant impact on distillation operation. When the pressure increases, the relative volatility of the mixed liquid will decrease, which is unfavorable for separation; When the pressure decreases, the relative volatility will increase, which is beneficial for separation. But when the pressure is too low, the equipment requirements are high, and the equipment cost increases. At the same time, the acetone-water liquid mixture system has a relatively high volatility at atmospheric pressure. Therefore, Wuxi Hongdinghua generally adopts atmospheric distillation when designing

Thermal condition of feeding

Bubble point feeding

Using indirect steam heating through a reboiler.

The condensation method of tower top condenser and cooling medium

The condensation temperature at the top of the tower is required to be no less than 30 ℃. The commonly used coolants are water and air, and cooling water is commonly used in industry. The cooling water can be natural water from river or lake. Due to local temperature limitations, the cooling water temperature is normally 10-25 ℃.

Heating medium for tower kettle

The commonly used heating medium is saturated Steam. Saturated steam is the most widely used heating medium. Because of the high heat transfer coefficient when saturated steam condenses, the heating speed can be accurately controlled by changing the steam pressure. Usually, saturated steam is used as the heating medium. Steam is easy to obtain, clean, and does not corrode the heating tube. The cost of the Acetone Distillation Tower will be correspondingly reduced, the Acetone distillation tower structure is also not complicated.

Selection of heat exchangers

Heat exchangers are commonly used process equipment in many industrial field, especially in petroleum and chemical production. In chemical plants, heat exchangers can serve as heaters, coolers, evaporators, and reboilers.

The shell-tube heat exchanger is currently the most widely used type of heat exchanger in chemical production as its’ simple structure, It is sturdy, it is easy to manufacture, there are wide range of metal materials can be used to build the heat exchanger. It also has large processing capacity, and strong applicability, especially in high temperature and high pressure compared to other heat exchangers. It is currently the main heat exchange equipment in chemical plants.

The advantages of a fixed tube plate heat exchanger are its simple structure, compactness, and low manufacturing cost; The inside of the pipe is not prone to scaling, and even if dirt is generated, it is easy to clean. The disadvantage is that the shell side maintenance is difficult, mainly suitable for situations where the temperature difference between the shell and the tube bundle is small, the materials outside the tube are relatively clean, and it is not easy to scale. So in this design, a fixed tube plate heat exchanger is used, with gas flowing outside the tube and liquid flowing inside the tube.

Pump selection

Chemical pumps mainly include centrifugal pumps, reciprocating pumps, rotary pumps, vortex pumps, etc. Due to the characteristics of wide range, wide flow rate, and wide head of centrifugal pumps, as well as their applicability to various control options for mild corrosive liquids, such as uniform flow rate, stable operation, low vibration, no need for special shock absorption foundations, and low equipment installation, maintenance and repair costs, usually HDH prefer to centrifugal pumps.